The REBEL Difference

Be REBELlious!

When your team has decades of experience in the upper limb market and has been a part of launching 3 of the leading hands in the global market, you have to ask…why design a fourth?

The answer is very simple, and comes from what makes an engineer, the desire & drive to improve things and make things that make people’s lives better!

For far too long upper limb myoelectric hand manufacturers have focused on features over function, larger than life promises, and mainly serving a population that has a variety of options.

At REBEL, we looked at what was missing – high end aesthetics, waterproof, smaller sizes, and addressing the needs of an under-served population.

Why REBEL?

- Prosthetic hands have reached design convergence

- Devices are only worn periodically and often rejected due to excessive weight

- Feature creep has made devices heavier and more complex and ultimately unreliable

- Clinical evidence indicates existing solutions fall short of meeting users’ need

- There is a need for an affordable way to resize/adjust

Get to know the REBEL hand

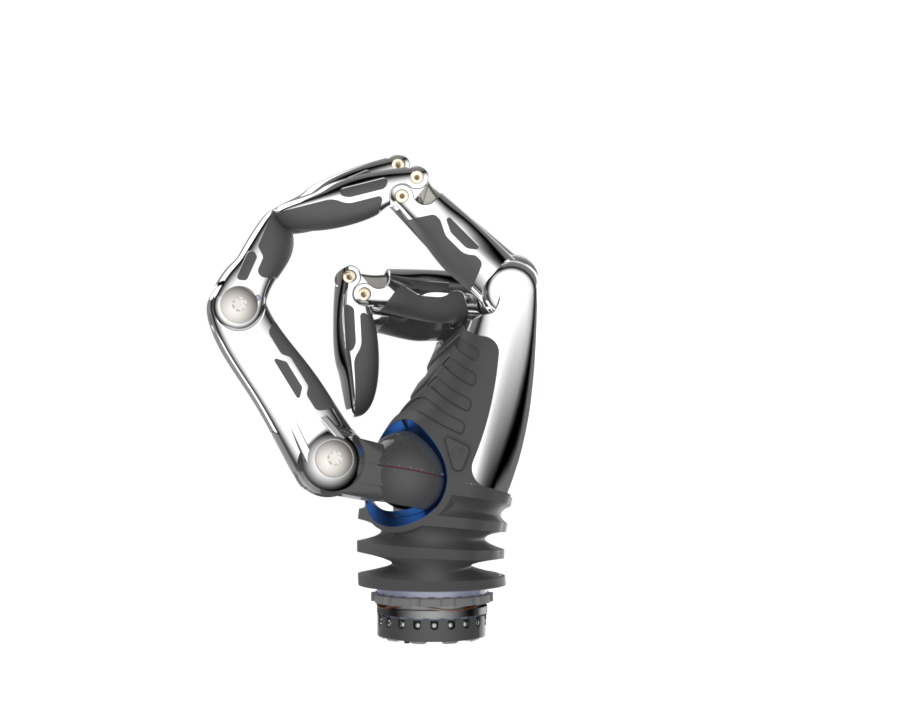

STRONG

Plastic is an amazing material, but it has no place in myoelectric multi-articulating hand designs.

This is not because it can’t deliver a strong grip, it can. But plastic can’t cope with the day to day accidents which happen to us all.

Because we know the goal of a prosthesis is to allow a user to return to their activities of daily living and being able to complete tasks such as opening a car door or picking up a deceptively heavy bag without worry, the REBEL digits and dorsal fairing are made from high strength aluminum, which is light yet strong.

Our custom coating is also incredibly hard wearing!

LIGHT

Most user’s first interaction with a bionic hand is almost always followed by the statement “Gosh, it’s kind of heavy.” This is often followed by the answer “It’s about the same weight as a human hand.” And the user just has to accept that.

While the answer may be true, a sound hand is connected to the rest of your body, where a prosthetic hand is on the outside of your body, hence the weight is a lot more noticeable.

Weight is imperative if these devices are going to be used, and are going to be useful!

With ideas taken from motorsports, we have taken a very novel approach to weight reduction rather than thinking, “what is the lightest material we can make this from?”

FUNCTIONAL

It has been really exciting to see the development in upper limb prosthetics over the last 15 years. Multi-grip hands, pattern recognition, touch sensors, etc. Although these functions and features can be massively useful, we [the engineers] have gotten carried away with thinking “wouldn’t it be amazing if…”

At REBEL we take a different approach. We want the hand to become an obvious tool, like a hammer or a screwdriver, objects which make life easier. If it’s not a function that will get used every day it goes in the trash.

With that in mind, we have limited the variety of grips we can deliver to reduce the motor count, but from feedback over the years we have ensured that our hand comes with an integrated flex wrist – this is a feature we feel all hands should have.

STYLISH

Hands in general are highly visible and used for most activities, so why not think of your prosthetic hand like you would a Rolex watch or a Hermes bag? Show it off, and know that it’s not just a pretty thing, but a dedicated tool as well.

We want people to think “WOW!”

REBEL hands are built from premium materials which allow them to look good not only when they come out of the box for the first time, but also 12 months, or 13 years later!

Meet our team of REBELS behind this important cause.

Mr Ted Varley

Mr Ted Varley is CEO of Rebel Bionics and a mechanical engineer with 20+ years of experience in commercial product development. Ted led the development of the award-winning Bebionic hand at Steeper before joining the Steeper board to manage all areas of prosthetics. Ted founded COVVI after the 2017 sale of Bebionic to Ottobock. The COVVI Nexus hand was launched in 2020. Ted now follows his passion to develop a fit for purpose paediatric prosthesis. His designs have received prestigious awards including from the Institute of Engineering and Technology. Ted has founded two Leeds based companies, which both export internationally and employ circa 30x people in the area.

Prof. Kia Nazarpour

Prof. Kia Nazarpour is co-founder of Rebel Bionics and an electronic engineer. He is currently a Professor of Digital Health and Care at the University of Edinburgh. Before his academic tenure, Kia worked for Touch Bionics, the manufacturer of the iLimb prosthesis, as Senior Engineer. He has received circa £13M funding from various sources including an EPSRC Challenge Award to work on next-generation prosthetic hands. His work on prosthetic limbs was recognised by UNESCO in 2018 for its impact on society and business.

Dr Matthew Dyson

Dr Matthew Dyson is co-founder of Rebel Bionics with a cross-disciplinary background in computer-science, neuroscience and biomedical engineering. He is a Research Fellow in paediatric prosthetics at Newcastle University. He has a particular interest in co-designing prosthetic solutions with children. Matthew acts as an expert advisor to the Starworks child prosthetics network.